New low-cost method

for determination of heating value of natural gas

Rybitskyi Ihor, Karpash Oleg, Darvay

Iryna, Karpash Maksym

Ivano-Frankivsk National Technical University of Oil and Gas

Karpatska St.,15, Ivano-Frankivsk, Ukraine 76018

(e-mail: mkarpash@nung.edu.ua,

rybitsky@nung.edu.ua )

Natural gas quality determination as

primary energy resource for our country can be assigned to energy security from

the point of view of its limited resources in Ukraine and the dynamics of the

continuous growth of prices for natural gas. Just so, since 1999, the price for

natural gas has increased at an average almost in 3 times for the population

and in 10 times for enterprises.

Heat, released by the natural gas

burning (heating value) is the main indicator of natural gas quality, the

indicator of its application.

The heating value of natural gas can

be determines in two ways:

- by the calculation method (for

component composition) [1];

- by the experimental method (using

the water calorimeter) [2].

Both methods for natural

gas heating value determination have a number of significant drawbacks

[8, 9], the main of which are:

- significant time and cost expenses for the research;

- inability of the heating value continuous

measurement (in real time) directly to the consumer.

For solving the above mentioned problems new method

have been developed and proved theoretically for natural gas heating value determination,

which is compatible to measuring of ultrasound velocity in a gas, carbon

dioxide content and to the usage of artificial neural networks as heating value

nonlinear approximates as the function of the complex specified parameters. These informative parameters were selected by

correlation analysis of natural gas heating value with a number of standard physical and chemical parameters of natural

gas, namely: hydrocarbons content (methane, ethane, propane, butane and higher

hydrocarbons), density, molar mass, ultrasound velocity in gas, carbon

dioxide content and nitrogen content [3].

Adequacy of a new express-method for gas heating value

measuring was tested with the usage of artificial neural network (SHNM) with

reference values of gas physical and chemical parameters [4] and real values of

natural gas parameters from the natural gas quality certificates, as defined in

one of the companies of Ivano-Frankivsk region.

The purpose of this article is to conduct experimental

investigation to establish the possibility of practical application of the

proposed method directly to the consumers of natural gas.

The essence of experimental investigation was in the

following: two identical samples of natural gas were selected simultaneously

from gas network. Thereafter one of the samples was analyzed by means of

specially developed experimental unit for heating value determination by the

proposed method. Another gas sample was put into the chromatograph serial type

KCH (industrial No. 3875) for component composition measuring and natural gas heating

value calculation. After the above-mentioned investigations were performed,

their results were compared. To reduce the influence of ambient temperature

readings for research measuring results, the investigations were conducted

simultaneously in same room.

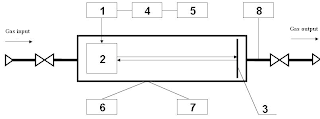

The experimental unit for gas heating value

determination has the following main blocks (Figure 1): gas preparation block

1, which includes water segregator, and flow-metering tube that is designed to

clean the samples of dust and moisture; sensors for measuring the sound

dispersion speed in gas 2; CO2

concentration in natural gas measuring unit, which consists of carbon dioxide

sensor serial-type IP 3-CO2 (industrial No. 1 / 3002) and gas analyzer 4

"DOZOR-C (industrial No. 3002).

1 – gas

preparation block, 2 - measuring chamber, 3 - CO2 feeding for natural gas, 4 -

block for measuring the sound dispersion speed in gas, 5 - pressure gauge;

6 - thermal

hygrometer 7 - thermometer, 8 - ultrasound stethoscope

Figure 1 -

Experimental unit for natural gas calorific value determination

The specifically designed and manufactured block for measuring the sound

dispersion speed in gas 2 (Figures 2, 3) is of particular interest. Block is a

tight construction made of stainless steel in cylindrical form, into which the

natural gas is supplied. The initial ultrasonic transducer of own production is

set up in the block. Its frequency is at up to 1 MHz, which works in couple

mode as emitter-receiver. At the calculated and clearly set distance of 57.7 mm upon condition of maximum energy

value of reflected signal receiving, the reflector, made of stainless steel

with diameter of 22 mm and a surface roughness Rz = 20, is set.

Also, the unit consists of 5 pressure gauges of type MT-2H (TR 33.2-33884768.001-2006)

thermal hygrometer of type OVT-6-7302 (industrial No. 08,082,341);

ultrasonic defectoscope DIO 562 (industrial No. 138).

1 –

generation-receiving circuit 2 - primary ultrasound transducer;

3

- reflector, 4 - processing results device, 5 – device output;

6 -

humidity sensor, 7 - temperature sensor, 8 - pressure sensor

Figure 2 -

Functional diagram of block for measuring the sound dispersion speed in gas

1 - tap 2 -

fitting, 3 - reflector, 4 - measuring chamber;

5 - piezoelectric

ultrasonic transducer, 6 – pressure gauge, 7 - connector;

8 - captivating

plate, 9 - temperature and humidity sensor

Figure 3 - Block

determining velocity of sound in gas

Technology for natural gas heating value determination

by means of the experimental unit is the next. Sample gas enters the measuring

chamber 2, where sound dispersion velocity is determined. To measure the carbon dioxide content in natural gas,

sample gas is needed to be additionally cleaned from mechanical impurities and

dried with the preparing samples block. The carbon dioxide content of

determined in the carbon dioxide determination block (3,4). Also the pressure,

temperature and humidity of gas sample are measured.

For the new method of heating value measuring 20

samples of natural gas were selected. By means of experimental unit the

following informative parameters were determined: ultrasound velocity in gas

and carbon dioxide content. Table 1 presents results of informative parameters

determination. Natural gas heating value was determined in Ivano-Frankivsk

National Technical University of Oil and Gas.

Table 1 - Results of the informative

parameters measuring

|

Gas sample No.

|

Sound dispersion

velocity in gas,

|

Carbon

dioxide content, %

|

Gas heating

value, kkal/m3

|

|

1

|

398,95

|

0,59

|

9086,4

|

|

2

|

410,82

|

0,52

|

8931,0

|

|

3

|

403,67

|

0,47

|

8838,2

|

|

4

|

406,64

|

0,56

|

8822,3

|

|

5

|

395,72

|

0,56

|

8961,6

|

|

6

|

402,66

|

0,55

|

8873,5

|

|

7

|

406,91

|

0,51

|

8879,2

|

|

8

|

409,34

|

0,56

|

8962,8

|

|

9

|

408,03

|

0,58

|

8772,4

|

|

10

|

409,19

|

0,57

|

9071,0

|

|

11

|

401,85

|

0,6

|

9167,6

|

|

12

|

403,9

|

0,62

|

9099,1

|

|

13

|

406,56

|

0,64

|

9042,2

|

|

14

|

399,18

|

0,57

|

9108,2

|

|

15

|

401,64

|

0,59

|

8957,8

|

|

16

|

404,13

|

0,6

|

8983,3

|

|

17

|

394,52

|

0,53

|

8885,5

|

|

18

|

399,63

|

0,56

|

9174,0

|

|

19

|

401,65

|

0,56

|

8825,2

|

|

20

|

403,9

|

0,56

|

8951,7

|

In order to calculate the natural gas

heating value by the results of measurements specially designed artificial

neural networks were used. 16 sets

of 20 informative parameters were selected to train the network and to test it

- 4 that were not used for training. At the entrance of ANN sound dispersion

velocity in gas and carbon dioxide content were given, and at the output - the

natural gas heating value. ANN testing results

are presented in Table 2.

As it is seen from the Table 2, the heating values,

defined by gas chromatograph, are equal to the values obtained by using

artificial neural network of developed method. Absolute error was 39.64 kkal/m3

and given to the range - 4.66 %. These results can be considered acceptable,

since for method control on data taken from the natural gas quality

certificates, the ranges error reached to 56%.

Experimental method of new method for natural gas

heating value measuring proved its adequacy and applicability.

Experimental unit required improvement, because it was

necessary to take into account the effect of humidity and temperature on gas

samples. For this purpose the block of sound dispersion velocity in gas velocity

was updated by the including humidity and temperature sensors directly into the

cylindrical measuring chamber unit. There have been improved the reflector –

the previous one was replaced by the concave reflector, made of stainless steel

with the diameter 20 mm and the curvature surface of 520, allowing to focus

acoustic signal from the primary converter and to increase the energy value of

received acoustic oscillations. In addition, the

block construction of sound dispersion velocity in gas provides the possibility

of distance regulation from the primary reflector to the transducer, that

allows get the maximum energy value of the reflected signal due to the radiated

frequency.

Table 2 - Results

of the natural gas heating value determination by the developed method

|

Sample No.

|

Heating value, received by the usage of ANN, kkal/m3

|

Heating value, received by the usage of gas chromatograph, kkal/m3

|

|

1

|

8815,8

|

8822,3

|

|

2

|

8948,5

|

8961,6

|

|

3

|

8958,8

|

9071,0

|

|

4

|

8924,9

|

8957,7

|

After corrective measures the industrial approval of

proposed method of natural gas heating value determination by the above

mentioned technique and results comparing with the data of gas samples

chromatography analysis was conducted in SE

"Ivano-Frankivskstandardmetrology" and JSC "Ivano-Frankivskgas.

The given measurement error, using the proposed

method, does not exceed 4%.

Currently works on the unit

industrial pattern production are performed.

Literary

1. Natural gas -- Determination of composition

with defined uncertainty by gas chromatography: DSTU ISO 6974 (parts 1-4): 2007 .- [Valid from 2007-01-01]

.- K: Derzhspozhivstandart Ukraine, 2007 .- 62 pp.

2. Natural burning gases. Method for heating value

determation by pressurized water calorimeter: GOST 27193-86 .- [Carried in

1988-01-01] .- M: USSR State Committee on Standards, 1987 .- 14 pp.

3. Karpash O.M. New informative parameters for natural

gas heating value determination / O.M. Karpash, I.Ya. Darvay, M.O. Karpash / /

Oil and Gas industry .-2008 .- № 4.-p.57-60.

4. Morrow Т.B. Development of a

low cost inferential natural gas energy flow rate prototype retrofit module,

Final report, DOE Cooperative Agreement No. DE-FC21-96MC33033, U.S. Department

of Energy, Morgantown, WV. Southwest Research Institute, San Antonio, TX.